Overview of the Working Principle of a Bolt Former Machine

A bolt former machine is a highly efficient automated equipment that performs continuous processing such as cutting, preforming, head forming, stamping, and chamfering of metal wire using multi-position cold heading or cold extrusion technology. Compared to traditional turning processes, the bolt former machine has significant advantages in material utilization, forming speed, and processing consistency, making it especially suitable for mass production of high-strength standard parts and custom parts.

Key Criteria for Selecting a Bolt Former Machine

Product Specifications and Complexity

When selecting a bolt former machine, it is important to consider the size range, geometric shape, and process difficulty of the product. Multi-position forming machines are suitable for bolts with complex structures (such as flanged, hex socket), while two-die and three-die machines are more appropriate for small to medium-sized fasteners with simple structures.

Type of Material and Strength Level

Different metal materials have a direct impact on the impact force, shear system, and die life of the forming machine. For example, high-strength materials such as stainless steel and alloy steel demand higher performance from the equipment. When selecting a machine, it is crucial to ensure that the bolt former machine has sufficient rigidity and energy reserves.

Production Capacity and Automation Level

For production lines that prioritize high efficiency, machines equipped with high-speed operation and automatic feeding systems should be selected, along with complementary automatic inspection, collection, and lubrication systems to enhance overall productivity and product consistency.

Equipment Size and Plant Space

Bolt former machines are relatively large. Prior to purchasing, it is necessary to plan the layout based on plant space, organize logistics pathways reasonably, and ensure the convenience of equipment installation, debugging, and maintenance.

Applicable Industry Scenarios for Bolt Formers

Automotive Manufacturing Industry

The automotive industry uses a large number of bolts in the chassis, engine, body structure with extremely high precision and strength requirements. Bolt formers can mass-produce high-precision, high-strength bolts to meet the stringent standards for safety and reliability in the automotive industry.

Construction and Infrastructure Field

Various standard and non-standard bolts are widely used in large-scale buildings, bridges, and steel structure projects. Forming machines can achieve stable mass production, suitable for processing various construction fasteners such as hex bolts and stud bolts.

Home Appliances and Electronics Manufacturing

Household appliances and electronic devices often use small bolts with precise dimensions and high surface requirements. Bolt formers, coupled with precise dies and subsequent processing techniques, can meet the dual requirements of appearance and size control in this industry.

High-end Machinery and Energy Equipment

Wind power, nuclear power, and heavy machinery equipment have extremely high requirements for the reliability and consistency of fasteners. Bolt formers demonstrate strong advantages in stability and long-term operation, making them key equipment for ensuring the quality of high-end manufacturing.

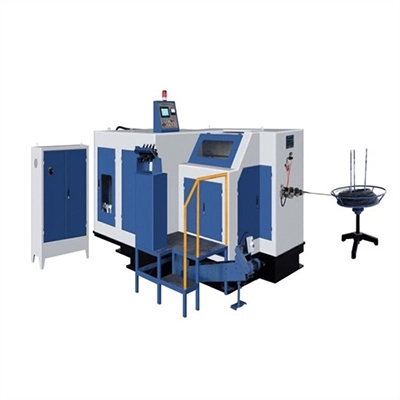

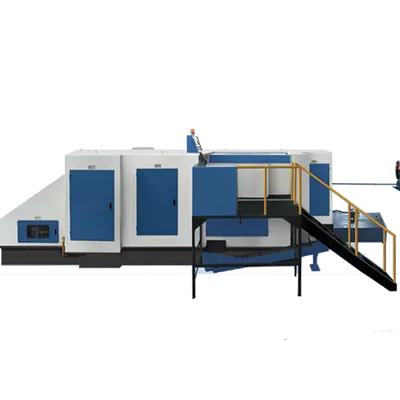

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文