In modern manufacturing, metal components such as fasteners, bolts, nuts, and rivets are widely used in industries like automotive, aerospace, machinery, construction, and electronics. To improve production efficiency, reduce material waste, and enhance part strength, cold heading forming machines play a crucial role as efficient and precise processing equipment. This article will focus on the principles, processes, and technological advantages of cold heading, helping readers gain a comprehensive understanding of this advanced forming method that replaces cutting with force.

Core Process of Cold Heading

The cold heading process generally includes the following main steps:

1. Raw Material Preparation: Suitable diameter metal rods are selected, straightened, cleaned, and lubricated to prepare for the subsequent forming steps.

2. Cutting to Length: The rods are cut into the required length blanks using mechanical tools, ensuring high precision and speed.

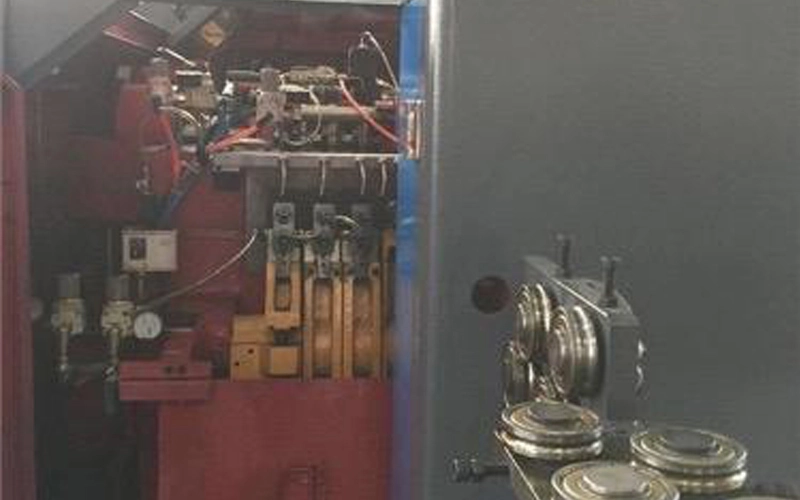

3. Initial Heading: The blank is placed into a mold cavity, and a punch applies high pressure to force the metal into the mold, creating a rough shape.

4. Multi-Station Heading (if applicable): For parts with complex structures, multiple forging operations are performed, such as pre-forming the head, extrusion of grooves, and pre-forming threads. Material automatically transfers between each station.

5. Part Ejection and Inspection: After forming, the workpiece is ejected from the mold. Some machines are equipped with in-line inspection systems to ensure consistent quality.

Significant Advantages of Cold Heading

High Efficiency

The cold heading forming machine operates at high speeds, producing hundreds of parts per minute, far exceeding traditional turning or milling methods. This makes it ideal for mass industrial production.

High Material Utilization

Traditional cutting processes remove a large amount of metal, causing significant waste. In contrast, cold heading forms the material through metal flow and extrusion, with almost no waste, achieving a material utilization rate of 85% to 95%.

High Strength of Parts

In cold heading, the metal fibers are not cut but instead flow and align according to the shape of the part. This results in improved mechanical properties for the finished product, significantly increasing tensile strength, shear strength, and fatigue resistance.

Stable Dimensions and High Precision

The mold controls the shape and size, ensuring consistent forming and reducing the need for further machining. This is beneficial for standardized and automated production.

Eco-friendly

The process operates at room temperature without heating or coolant, resulting in low energy consumption and minimal emissions, aligning with sustainable manufacturing principles.

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文