What Is a Cold Header Machine?

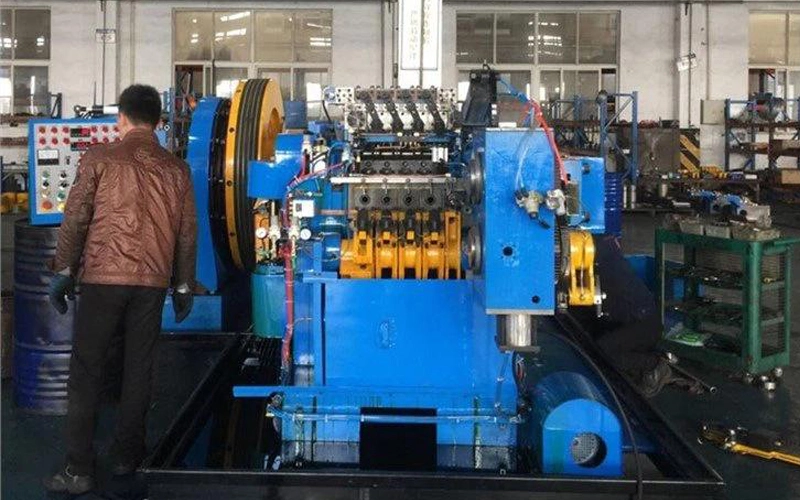

A cold header machine, also known as a cold forming machine or a cold heading machine, is a type of machine that is used to form metal parts from wire or rod stock without the need for heat. Cold heading is a process of forming metal parts by applying pressure to the material using a series of dies and punches.

In a cold header machine, the wire or rod stock is fed into the machine and then clamped in place. A series of punches and dies are used to shape the material, creating the desired form of the part. The process is carried out at room temperature, which is why it is called "cold" forming.

Cold header machines are used to produce a wide range of metal parts, such as bolts, screws, pins, rivets, and other fasteners. They are often used in industries such as automotive, aerospace, and construction, where high-quality and precise metal parts are required. Cold heading is a cost-effective and efficient process that produces parts with excellent strength and durability.

How Does a Cold Header Machine Work?

A typical cold heading process begins with feeding a coil or wire of metal into the machine. The wire is then straightened and cut into precise blanks. These blanks are transferred through one or more die stations, where they are progressively formed into the desired shape using high-speed mechanical or hydraulic force.

Cold forming processes may include:

Upsetting: Compressing the blank to increase its diameter

Extrusion: Forcing metal to flow through a die cavity

Heading: Creating complex shapes like bolt heads

Piercing: Creating holes or indentations

The entire operation happens at high speed—up to hundreds of parts per minute—making cold headers ideal for mass production.

Cold Heading vs. Hot Forging: What's the Difference?

Feature | Cold Heading | Hot Forging |

Temperature | Room temperature | High temperature (over 1,000°F/538°C) |

Surface Finish | Excellent | Rougher finish |

Material Strength | Increased due to work hardening | May require heat treatment afterward |

Tolerance | High precision | Less precise |

Energy Consumption | Lower | Higher |

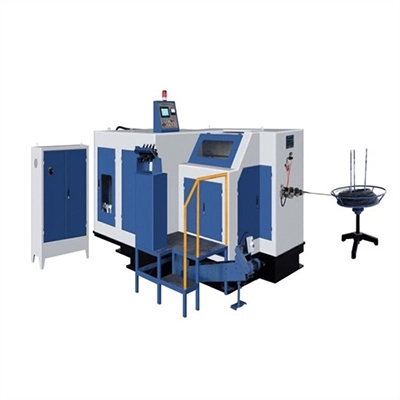

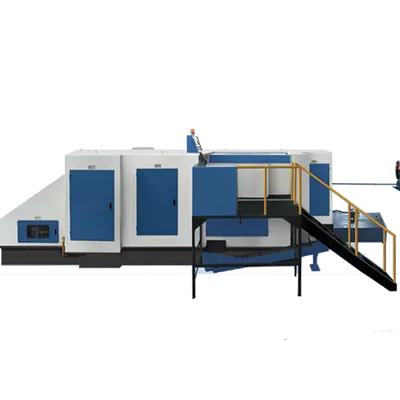

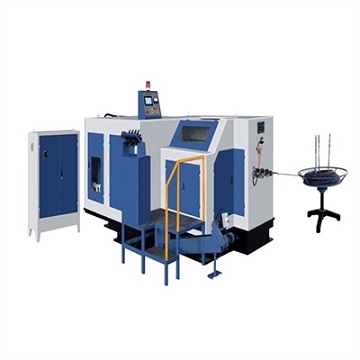

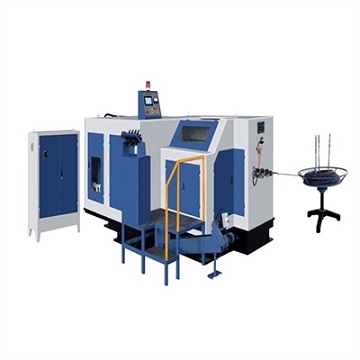

Types of Cold Header Machines from SHINETOP

As one of the most professional cold heading machine manufacturers in China, SHINETOP offers a full range of machines tailored to fastener and parts production:

Multi-Station Bolt Forming Machines

Designed for the mass production of standard and special bolts with superior head accuracy and thread quality.

2. Multi-Station Parts Cold Forging Machines

Ideal for forming complex and multi-step parts used in automotive and mechanical applications.

Five Die Five Blow Bolt Parts Forming Machine

Six Die Six Blow Bolt Parts Forming Machine

Seven Die Seven Blow Bolt Parts Forming Machine

3. Thread Cold Rolling Machine

For high-speed precision thread forming, with excellent surface finish and thread accuracy. Suitable for various bolt types and shafted components.

Each machine type is engineered with a robust structure, precise transmission, and easy-to-operate automation systems.

Benefits of Cold Heading

Cold heading offers several advantages over traditional metalworking techniques:

High production efficiency: Capable of producing parts at high speed with low cycle times

Excellent material utilization: No cutting or grinding means little to no material waste

Superior mechanical properties: Cold working improves strength and grain structure

Dimensional consistency: High repeatability across large production batches

Cost-effective: Reduces raw material use, energy consumption, and secondary processes

Common Applications of Cold Header Machine

Cold heading is widely used in industries that require fasteners and precision parts in large volumes, such as:

Automotive – Bolts, shafts, axles, spark plug shells

Construction – Screws, anchors, rivets

Electronics – Contact pins, micro screws

Aerospace – Specialty fasteners and lightweight components

Machinery – Custom cold-formed parts with complex shapes

SHINETOP's Technology Advantages

At SHINETOP, we're committed to delivering performance-driven machines backed by leading technologies:

Robotic Tool Change System

Switch between punch blocks and die blocks in as little as 3 minutes. Six sets can be pre-installed in the tool magazine, ensuring efficient small-batch production with high precision.

Hybrid Tool Change Flexibility

Our machines allow dies and punches to be changed either simultaneously or independently, increasing flexibility and reducing downtime.

Certified Quality Assurance

All machines are ISO9001:2008 certified and CE marked. Each unit undergoes strict inspection, functional testing, and performance verification before delivery.

Global Service & Support

Our machines are exported to Russia, India, Turkey, Brazil, South Korea, and many other countries, with a reputation for reliability and service excellence. Every customer enjoys 1-year warranty coverage, technical support, and training. Our service doesn’t end with delivery—it starts there.

FAQs About Cold Heading

Q1: What materials are suitable for cold heading?

Low- and medium-carbon steel, stainless steel, brass, copper, and aluminum alloys are commonly used.

Q2: How does cold heading compare to hot forging?

Cold heading is cleaner, faster, and more material-efficient, though hot forging is preferred for very large or heat-sensitive parts.

Q3: Can SHINETOP machines handle custom part designs?

Yes. We offer tailor-made solutions to fit your unique production needs, from bolt to complex formed parts.

Q4: Do you provide installation and training services?

Absolutely. We offer remote guidance, video tutorials, and on-site technician support where needed.

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文