In today's highly competitive manufacturing landscape, choosing the right production method can significantly impact product quality, production speed, and cost efficiency. For bolt and nut manufacturing, cold forging and machining are two widely used methods. But which one is better for your production needs?

Let's dive into the key differences, advantages, and ideal use cases of cold forging versus machining so that you can make the most informed choice.

What Is Cold Forging?

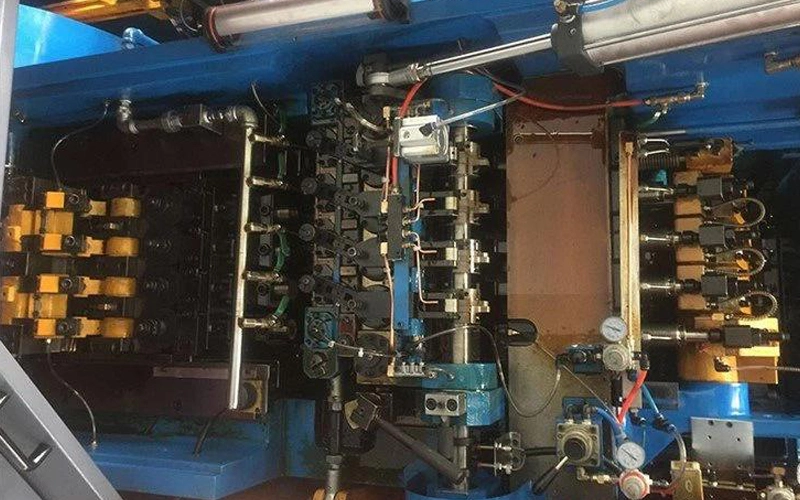

Cold forging—also known as cold heading—is a metal forming process in which raw material (usually wire or rod) is shaped at room temperature using high-pressure dies and punches.

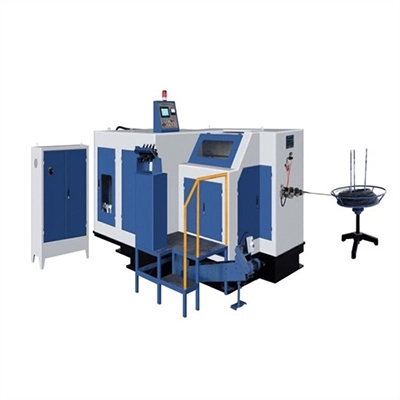

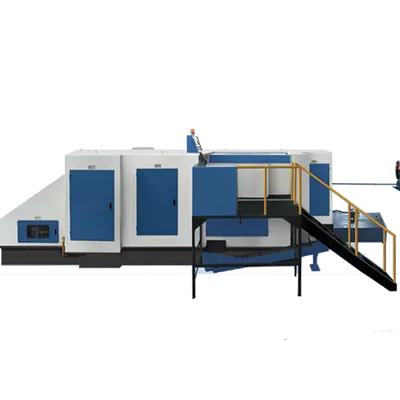

At Shengtuo Machine, we specialize in multi station cold forging machines such as 3-die 3-blow, 4-die 4-blow, 5-die 5-blow, and up to 7-die 7-blow configurations. These machines enable high-speed, multi-step forming of bolts ranging from M6 to M30 and lengths from 50mm to 355mm.

What Is Machining?

Machining is a subtractive manufacturing process that involves cutting, drilling, turning, or milling raw materials into desired shapes using CNC machines or lathes. This method is precise but usually slower and generates more material waste.

Cold Forging vs. Machining: Key Differences

Feature | Cold Forging | Machining |

Process Type | Forming (no material loss) | Cutting (material removal) |

Production Speed | High-speed, multi-station | Moderate to slow |

Material Waste | Minimal | High (chips/scrap) |

Strength of Final Part | High (grain flow retained) | Lower (grain cut) |

Surface Finish | Smooth, requires minimal finishing | Requires secondary processing |

Tool Cost | Higher initial die cost | Lower initial setup |

Best for | High-volume, complex shapes | Low-volume, complex customization |

Why Cold Forging Is the Superior Choice for Bolts

1. Higher Strength and Durability

Cold forging enhances the mechanical properties of bolts by aligning the grain flow with the part geometry. This results in parts with greater tensile strength, fatigue resistance, and impact tolerance compared to machined bolts.

2. Material Savings

Cold forging achieves near-net-shape production with minimal material waste. This is especially important in mass production scenarios where cost per piece must be optimized.

At Shengtuo Machine, our cold forging nut former machine is engineered to maximize material efficiency and reduce scrap generation across high-speed, multi-station operations.

3. Superior Production Efficiency

Multi-station forming machines—like the ones offered by Shengtuo—can produce complex parts such as hex head screws, flange bolts, or hollow fasteners in one automated cycle. Compared to machining, this drastically reduces cycle time and increases throughput.

4. Scalability for Industrial Applications

From automotive and aerospace to railway, wind power, and marine industries, cold forging is ideal for producing high-strength, high-volume parts with consistent quality.

5. Eco-Friendly and Cost-Effective

Cold forging consumes less energy than machining or hot forging and reduces environmental impact through lower waste and emissions. For manufacturers aiming for sustainable production, this process checks all the boxes.

Applications of Cold Forging

At Shengtuo Machine, our solutions are used to manufacture:

Inside/outside hexagon bolts

Flange screws

Hollow or solid fasteners

Non-standard shaped parts

We also provide customized multi-station forming machines tailored to specific application needs—especially for customers requiring non-standard parts or specialty alloys like titanium, aluminum, copper, and stainless steel.

Certified Quality You Can Trust

Shengtuo Machine is ISO9001:2008 certified and our machines are CE certified, ensuring international-quality standards. Our equipment delivers precision, reliability, and long-term performance trusted by manufacturers worldwide.

While machining has its niche in custom, low-volume production, cold forging remains the gold standard for high-volume, high-strength bolt and nut manufacturing.

If you’re looking to boost your production efficiency, reduce costs, and improve part quality—cold forging is your answer.

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine

Thread Cold Rolling Machine

ST-4R-50 High-Speed Thread Rolling Machine ST-8R-83(120) High-Speed Thread Rolling Machine ST-6R-80 High-Speed Thread Rolling Machine ST-4A-50 High-Speed Thread Rolling Machine ST-4A-25 High-Speed Thread Rolling Machine ST-10N-150 High-Speed Thread Rolling Machine ST-30N High-Speed Thread Rolling Machine ST-60N(M16-150) High-Speed Thread Rolling Machine ST-60N(M16-200) High-Speed Thread Rolling Machine ST-12N-150 High-Speed Thread Rolling Machine ST-3A-25 High-Speed Thread Rolling Machine ST-3 High-Speed Thread Rolling Machine ST-80N High-Speed Thread Rolling Machine ST-90S High-Speed Thread Rolling Machine ST-100-M40 High-Speed Thread Rolling Machine ST-70N End Milling Machine English

English 中文

中文